WASHINGTON—If the global auto industry were a country, it would represent the world’s sixth largest economy.

This claim, according to The International Organization of Motor Vehicle Manufacturers, is supported by the global production of 66 million cars, vans, trucks, and buses, and 9 million workers, according to 2005 data.

Globally, the United States ranks third, at 5.7 million vehicles produced, after China’s 13.7 million and Japan’s 7.9 million.

In 2008 when Chrysler LLC and General Motors Corp., two of the Detroit’s Big Three, faced bankruptcy, had the government allowed Chrysler and GM to collapse, the U.S. global market share would have plummeted, and domestic markets dominated by foreign firms.

Already, international firms, mainly Toyota Motor Co., Honda Motor Co., and Hyundai Motor Co., operating in the United States have reached over 50 percent in market share. Back during its heyday in 1945, the U.S. auto manufacturing landscape was 95 percent domestic.

At the end of 2008, when Chrysler and GM faced a dire need for billions of dollars in financing, the U.S. government granted financing under the Troubled Asset Relief Program (TARP), offering an alternative, a government-sponsored Chapter 11 bankruptcy, effectively saving the industry.

Looking back, after just a short period of time, the results of the government bailouts have defied detractors who predicted taxpayer money would be lost. Lawmakers and business executives have lauded the bailout as a success.

Auto manufacturing employs 1 million U.S. workers, second only to computers and electronics, which employs 1.5 million.

Auto manufacturing is also an important job multiplier. The supply of parts to auto manufacturers involve steel, plastic, rubber, and glass industries, and are used to make the bodies, interiors, tires, gaskets, and windows of new cars.

Auto industry also invests substantially in research and development. Responding to calls for improved vehicle safety, performance, and fuel efficiency, the industry invested $16 billion in R&D in 2007 alone.

Between March 2008 and March 2009, the industry shed 410,000 jobs. The U.S. Treasury estimated the loss of 1.1 million jobs, had Chrysler and GM been allowed to collapse.

The government now reports that employment in the sector has stabilized.

In April of last year, GM repaid the remainder of its $6.7 billion in TARP loans, five years ahead of schedule. The remaining U.S. government stake in the company is $2.1 billion in preferred stock and 60.8 percent in common equity.

Chrysler Financial, which received $1.5 billion to support auto financing, has repaid its loans, and Chrysler announced its first operating profit since the beginning of the crisis.

Ford earned $4.7 billion in the first six months of 2010, its largest first-half profit since 1998, and GM earned $2.2 billion. Long-term viability is still threatened by projected low sales volumes.

According to the Center for Automotive Research, experts believe it will take years for the industry to reach pre-recession domestic sales of 15 million, a number believed to be sustainable in the long term. Estimates for 2010 range from 12 to 13.2 million units.

Continued on the next page...

This claim, according to The International Organization of Motor Vehicle Manufacturers, is supported by the global production of 66 million cars, vans, trucks, and buses, and 9 million workers, according to 2005 data.

Globally, the United States ranks third, at 5.7 million vehicles produced, after China’s 13.7 million and Japan’s 7.9 million.

In 2008 when Chrysler LLC and General Motors Corp., two of the Detroit’s Big Three, faced bankruptcy, had the government allowed Chrysler and GM to collapse, the U.S. global market share would have plummeted, and domestic markets dominated by foreign firms.

Already, international firms, mainly Toyota Motor Co., Honda Motor Co., and Hyundai Motor Co., operating in the United States have reached over 50 percent in market share. Back during its heyday in 1945, the U.S. auto manufacturing landscape was 95 percent domestic.

At the end of 2008, when Chrysler and GM faced a dire need for billions of dollars in financing, the U.S. government granted financing under the Troubled Asset Relief Program (TARP), offering an alternative, a government-sponsored Chapter 11 bankruptcy, effectively saving the industry.

Looking back, after just a short period of time, the results of the government bailouts have defied detractors who predicted taxpayer money would be lost. Lawmakers and business executives have lauded the bailout as a success.

Saving an Industry

TARP is widely acknowledged for saving the American auto industry.Auto manufacturing employs 1 million U.S. workers, second only to computers and electronics, which employs 1.5 million.

Auto manufacturing is also an important job multiplier. The supply of parts to auto manufacturers involve steel, plastic, rubber, and glass industries, and are used to make the bodies, interiors, tires, gaskets, and windows of new cars.

Auto industry also invests substantially in research and development. Responding to calls for improved vehicle safety, performance, and fuel efficiency, the industry invested $16 billion in R&D in 2007 alone.

Between March 2008 and March 2009, the industry shed 410,000 jobs. The U.S. Treasury estimated the loss of 1.1 million jobs, had Chrysler and GM been allowed to collapse.

The government now reports that employment in the sector has stabilized.

In April of last year, GM repaid the remainder of its $6.7 billion in TARP loans, five years ahead of schedule. The remaining U.S. government stake in the company is $2.1 billion in preferred stock and 60.8 percent in common equity.

Chrysler Financial, which received $1.5 billion to support auto financing, has repaid its loans, and Chrysler announced its first operating profit since the beginning of the crisis.

Ford earned $4.7 billion in the first six months of 2010, its largest first-half profit since 1998, and GM earned $2.2 billion. Long-term viability is still threatened by projected low sales volumes.

According to the Center for Automotive Research, experts believe it will take years for the industry to reach pre-recession domestic sales of 15 million, a number believed to be sustainable in the long term. Estimates for 2010 range from 12 to 13.2 million units.

Continued on the next page...

Extending Credit

The TARP bailouts were combined with programs designed to comprehensively address depressed new vehicle purchases and spur demand.

During the downturn, consumers lost access to credit, and thus the ability to finance new car purchases. The Federal Reserve estimated that lack of financing was preventing 1 million to 1.5 million vehicle purchases per year.

To counteract the problem, the Treasury Dept. launched an aggressive program tasked with unlocking loan credit for vehicle purchases. The Term Asset Backed Securities Loan Facility supported more than 2.6 million auto loans and leases, the Fed estimated.

To entice consumers—likely to stretch the useful life of their vehicles under the downturn either due to job loss, lower wage earnings due to job changes, or unemployment—to purchase or lease new vehicles, the government offered incentives of up to $4,000 to buy a new, and more fuel efficient, vehicle.

Under the highly successful “Cash for Clunkers” program, consumers turned in 690,000 old cars during the summer of 2010, driving sales of over 2 million new cars, at a total taxpayer cost of over $3 billion.

“Cash for Clunkers had a large stimulating effect on the industry as dealers sold hundreds of thousands of additional vehicles beyond the norm for this time of year,” states a report by the Center for Automotive Research.

Continued growth and success of the U.S. auto industry relies on access to new and developing markets, but Korea is also a big player in the automotive industry, ranking sixth globally.

The recently agreed FTA is widely seen as an improvement over previous deals, but still doesn’t go far enough for some, putting the ability of Congress to ratify the agreement into question. Unions, in particular, are divided over its predicted impact for U.S. workers in particular.

The United States has long suffered a significant trade imbalance with Korea, importing 400,000 vehicles in 2009, mostly Hyundais and Kias, while exporting less than 6,000 vehicles to Korea the same year.

U.S.-Korea cooperation in the autos sector is interconnected due to a Hyundai manufacturing facility operating in the United States, but the facility imports 60 percent of its parts, limiting the potential positive impact for U.S. workers, as well as weakening the domestic parts manufacturing economy overall.

The United Steelworkers (USW), representing workers in a wide swath of basic industries supporting auto manufacturing, opposes the FTA. USW President Leo Gerard said in a statement, “The FTA will only ensure a continuation of the negative impact of this import flood on domestic production and employment.”

The United Autoworkers Union supports the deal, particularly agreements which would reduce South Korean tariffs to U.S. exports faster than the opening of U.S. markets, giving “U.S. automakers the time to reverse the damage caused by decades of South Korean protectionism.”

The future of the FTA will be decided in the next few months, when Congress decides whether or not to accept it.

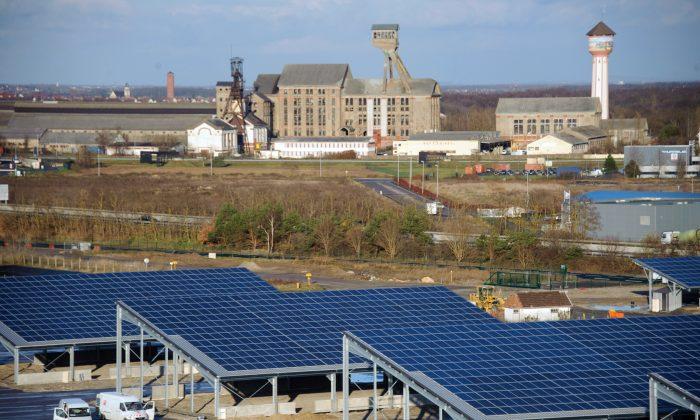

Besides expanding trade, opportunities on the horizon for auto manufacturing in the United States will involve new technology advancements, particularly in batteries and components that will support plug-in hybrid electric vehicles.

A set of global initiatives supporting new fuel efficiency standards are changing the industry landscape, tipping the scales in favor of smaller, fuel-efficient vehicles. The downside for U.S. manufacturers, despite their movement in this direction, is that these vehicles typically offer a lower profit margin than the larger vehicles the United Staes has traditionally built.

U.S. auto manufacturers will face stiff competition from global competitors during 2011, a year that is likely to reveal the future of one of the nation’s oldest and most successful industries.

During the downturn, consumers lost access to credit, and thus the ability to finance new car purchases. The Federal Reserve estimated that lack of financing was preventing 1 million to 1.5 million vehicle purchases per year.

To counteract the problem, the Treasury Dept. launched an aggressive program tasked with unlocking loan credit for vehicle purchases. The Term Asset Backed Securities Loan Facility supported more than 2.6 million auto loans and leases, the Fed estimated.

To entice consumers—likely to stretch the useful life of their vehicles under the downturn either due to job loss, lower wage earnings due to job changes, or unemployment—to purchase or lease new vehicles, the government offered incentives of up to $4,000 to buy a new, and more fuel efficient, vehicle.

Under the highly successful “Cash for Clunkers” program, consumers turned in 690,000 old cars during the summer of 2010, driving sales of over 2 million new cars, at a total taxpayer cost of over $3 billion.

“Cash for Clunkers had a large stimulating effect on the industry as dealers sold hundreds of thousands of additional vehicles beyond the norm for this time of year,” states a report by the Center for Automotive Research.

Future 2011

Recent negotiations of the U.S.-Korea Free Trade Agreement (FTA) hinged on the government’s ability to win concessions for the auto industry, mainly Ford, that would enhance the industry’s success without harming U.S. jobs.Continued growth and success of the U.S. auto industry relies on access to new and developing markets, but Korea is also a big player in the automotive industry, ranking sixth globally.

The recently agreed FTA is widely seen as an improvement over previous deals, but still doesn’t go far enough for some, putting the ability of Congress to ratify the agreement into question. Unions, in particular, are divided over its predicted impact for U.S. workers in particular.

The United States has long suffered a significant trade imbalance with Korea, importing 400,000 vehicles in 2009, mostly Hyundais and Kias, while exporting less than 6,000 vehicles to Korea the same year.

U.S.-Korea cooperation in the autos sector is interconnected due to a Hyundai manufacturing facility operating in the United States, but the facility imports 60 percent of its parts, limiting the potential positive impact for U.S. workers, as well as weakening the domestic parts manufacturing economy overall.

The United Steelworkers (USW), representing workers in a wide swath of basic industries supporting auto manufacturing, opposes the FTA. USW President Leo Gerard said in a statement, “The FTA will only ensure a continuation of the negative impact of this import flood on domestic production and employment.”

The United Autoworkers Union supports the deal, particularly agreements which would reduce South Korean tariffs to U.S. exports faster than the opening of U.S. markets, giving “U.S. automakers the time to reverse the damage caused by decades of South Korean protectionism.”

The future of the FTA will be decided in the next few months, when Congress decides whether or not to accept it.

Besides expanding trade, opportunities on the horizon for auto manufacturing in the United States will involve new technology advancements, particularly in batteries and components that will support plug-in hybrid electric vehicles.

A set of global initiatives supporting new fuel efficiency standards are changing the industry landscape, tipping the scales in favor of smaller, fuel-efficient vehicles. The downside for U.S. manufacturers, despite their movement in this direction, is that these vehicles typically offer a lower profit margin than the larger vehicles the United Staes has traditionally built.

U.S. auto manufacturers will face stiff competition from global competitors during 2011, a year that is likely to reveal the future of one of the nation’s oldest and most successful industries.