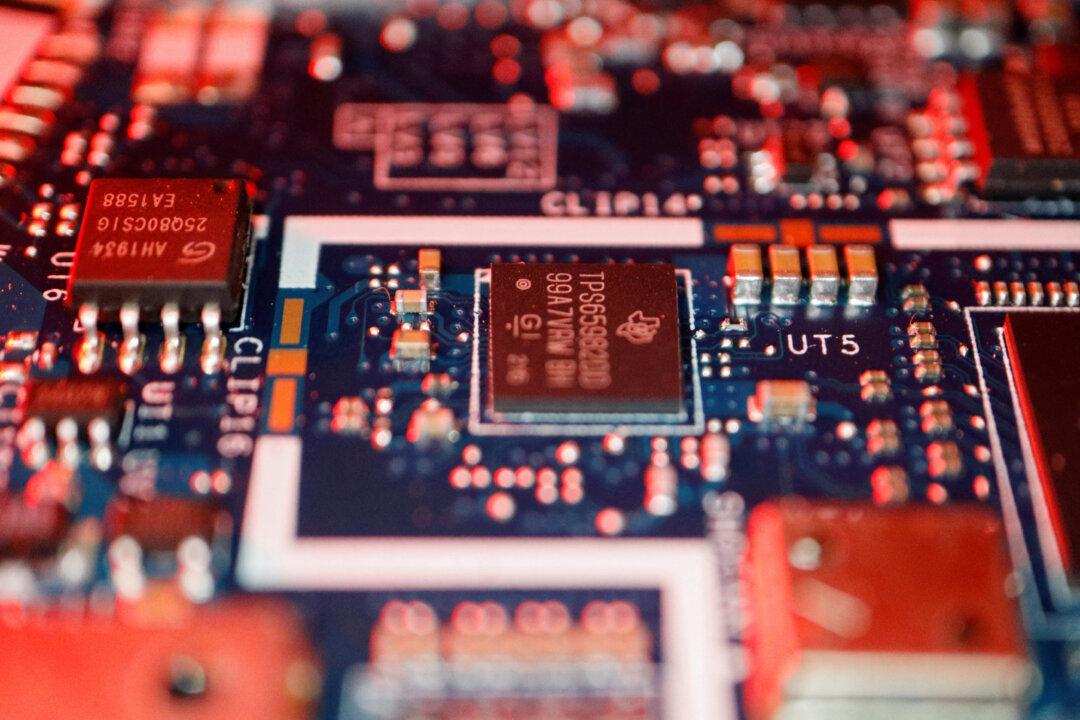

The world’s largest contract chipmaker is opening a second fabrication plant in Arizona to produce advanced semiconductor technology, as the U.S. government seeks to shore up America’s chipmaking supply chain.

Taiwan Semiconductor Manufacturing Co. (TSMC), a major supplier to Apple, announced today that the second fabrication plant (or “fab”) will bring the company’s total investment in its manufacturing site north of Phoenix to $40 billion. The fab has started construction and is slated to begin production of cutting-edge 3-nanometer process technology in 2026.