MRSA (Methicillin Resistant Staphylococcus Aureus) superbug.

The BioElectricSurface Research Team has utilised nano-particles on textiles which are used in hospital drapes, bed linens, and upholstery. The Nano-materials, which are a thousand times smaller than a human hair, possess properties that the team has harnessed to develop this technology to fight MRSA.

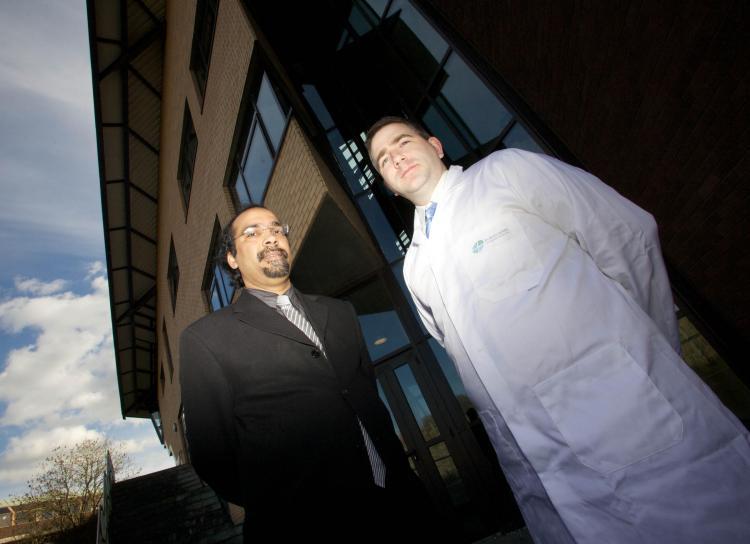

The Epoch Times spoke with Mr John Mulcahy, Project Manager at the University of Limerick, about the novel approach, currently with patent pending, which could help to eradicate the MRSA bug in hospitals worldwide.

Using the new technology, MRSA-killing particles are embedded into a standard textile, and the resulting material can be used in a hospital environment. What makes this approach different to others that have tried to combat the MRSA bug is the way in which the active nano-particles are embedded in the textiles. “It is something that has not been done before, and therefore it is fairly sought after because it can make a big difference in hospital environments where MRSA’s are so prevalent,” said Mr Mulcahy.

Mr Mulcahy says that the UL team’s process should work in other areas of bacterial control. “MRSA is one of the headline bugs out there at the moment but there are actually quite a few different types of bugs on which this particular technology can be effective,” he said.

The nano-particles are photo-active; therefore, when light hits the nano-particles they are activated, and emit a chemical that works against the MRSA bug. As long as those particles are present, the material will continue to function as a textile that will not transport the MRSA bug, thus reducing the spread of MRSA in a hospital.

Staff working in a hospital who may tend to many different patients over the course of a working shift would be ideal candidates for wearing uniforms made from this textile, which should aid the reduction in the spread of MRSA.

I asked Mr Mulcahy how long the textile would function for, and whether it was just a short term protection. “Any garments used in a hospital environment would be sterilised using other processes as well, so it has the potential to last … you are not talking about minutes, you are talking about days and weeks, potentially,” said Mr Mulcahy.

Since the initial statement with respect to the new process, several companies have contacted the University with a view to producing products using the process, and to taking the technology further, said Mr Mulcahy.

“There is quite a bit of interest there in the technology,” said Mr Mulcahy.

The global problem with MRSA and other bacterial infections that are resistant to antibiotics places the newly discovered process in a strong market position.

The fact that the material will be photo-active means that it is best suited to textiles that are regularly exposed to light, even at low levels. Even materials such as cleaning cloths may be suitable; however, this is not the initial intended market, said Mr Muclahy, although some companies have expressed interest in this area.

Co-ordinator of this research, Dr Syed Tofail of the Materials and Surface Science Institute at the University of Limerick, expressed his excitement at the development of this new method, as the social impacts and commercial potential for such technologies are very high. The US and European market size for medical textiles was estimated to be over $7 billion (5 billion euro). “Our technology will be used to produce practical, economical and effective products for this huge potential market,” he said.

The MRSA bug is one of the major causes of hospital-acquired infections. In June 2007, the European Centre for Disease Prevention (ECDC) identified antibiotic-resistant micro-organisms as the most important infectious disease threat in Europe. One in 10 patients entering a European hospital can expect to catch an infection caused by drug-resistant microbes. Every year, around 3 million people in the EU catch a healthcare-associated infection, resulting in approximately 50,000 deaths.

World Health Statistics from 2007 show that there are 7.94 million nurses registered in Europe and the USA. Assuming the average cost of a standard reusable uniform to be around $40 (28 euro), the team estimates a total annual value of $634 million (447 million euro) for this segment alone.