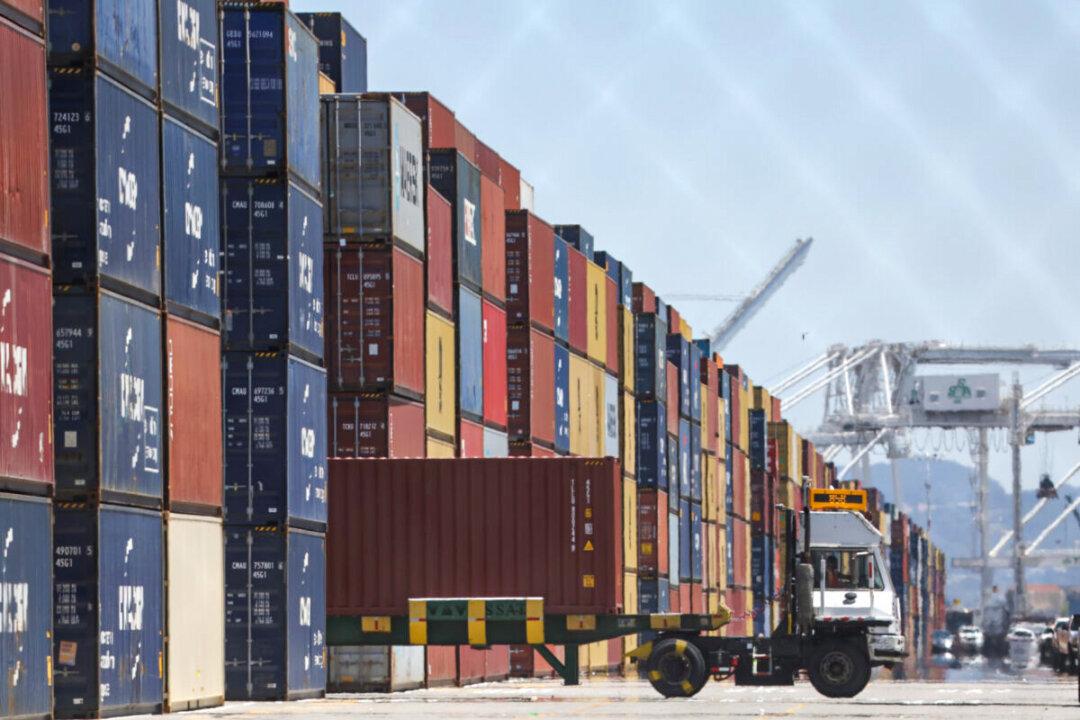

Global supply chains are changing their inventory models, shifting from “just-in-time” (JIT) to “just-in-case” (JIC) models amid supply disruptions and uncertainties, according to SAP UK.

Almost every organization in the UK admits that their supply chain needs improvement, with more than half admitting to needing a significant improvement to the supply chains, says a June 8 SAP press release.