Scientists have developed a new method to differentiate very weak and short sound waves from longer ones. When used in acoustic imaging, the technology makes it possible to detect only the outline of objects.

Reverberated sound can make objects visible. The shipping industry uses sonar to acquire information about the seabed or shoals of fish, and gynecologists use ultrasound images to study fetuses in the womb. Material testing procedures that regularly check for fissures in rail tracks or aircraft support structures also rely on ultrasound.

To understand just how the new acoustic edge detector works, it is important to know that sound waves are reflected off edges in a remarkable way: The acoustics near the edges is dominated by so-called evanescent waves. These waves have a much shorter wavelength than the incident sound waves that produce them. As the evanescent waves decay very fast as they propagate, they can only be measured in close proximity to the edge.

Methods to recover information contained in these waves have been developed in the past; however, the new method intensifies the evanescent waves and differentiates them from larger sound waves that are reflected in the “normal” way.

“This type of measuring method delivers similar results to the edge detection filter in an image-processing software, which allows the outline of prominent photo objects to be identified with the click of the mouse,” explains Chiara Daraio, professor of mechanics and materials at ETH Zurich.

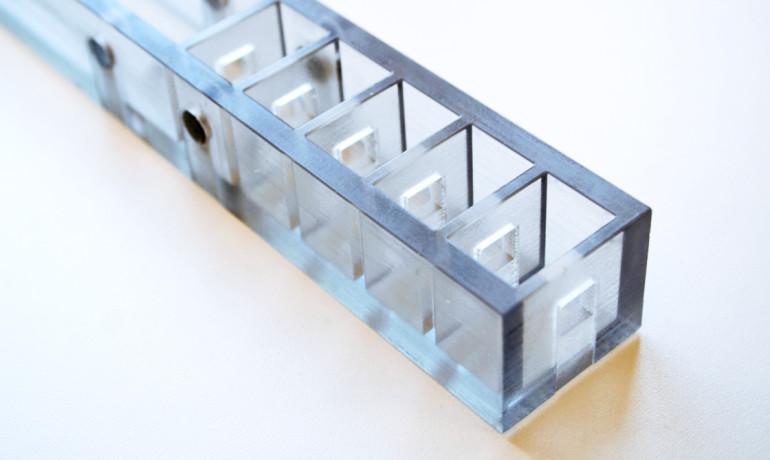

3D-Printed Structure

A new polymer structure, developed and produced with 3D-printing by postdoc Miguel Molerón, is central to the new method.

The structure is a pipe with a square cross-section, the inside of which is divided into five adjoining resonance chambers connected via small windows. “The resonance achieved by this structure intensifies the evanescent waves, and the successive chambers filter out the longer waves,” explains Molerón. At the head of the structure, four microphones measure the transmitted sound.