Industrial innovation has slowed down in the United States mainly because of imports from China, according to a recent study.

The findings of the study support President-elect Donald Trump’s negative stance on free trade and globalization. But can Trump’s tougher trade policies alone help bring innovation back to the United States?

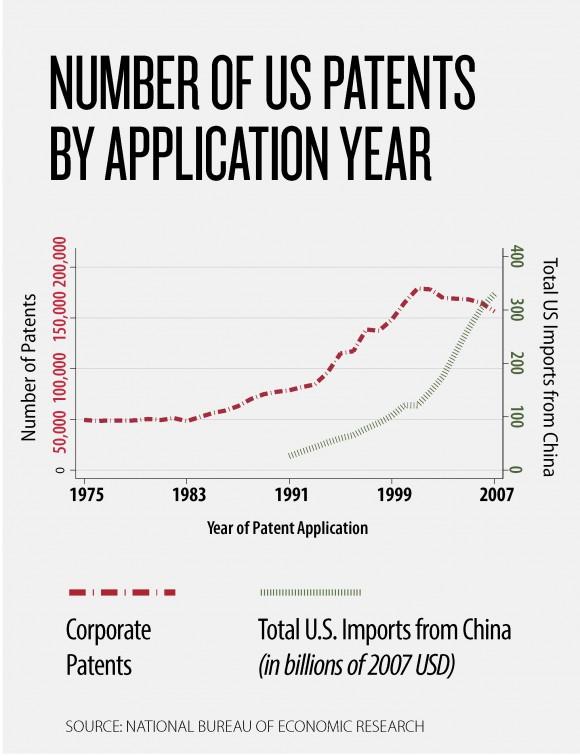

The report published by the National Bureau of Economic Research shows that imports from China increased competition and therefore hampered industrial innovation in the United States over the past two decades. The scholars measured innovation by looking at the number of patent applications by U.S.-based manufacturers.

“Our results suggest that the China trade shock reduces firm profitability in U.S. manufacturing, leading firms to contract operations along multiple margins of activity, including innovation,” stated the authors of the report, economists David Autor from MIT, David Dorn from the University of Zurich, Gordon Hanson from the University of California–San Diego, and Pian Shu and Gary Pisano from Harvard Business School.

The analysis starts with data from 1991, when the Chinese imports began to grow in earnest. Imports accelerated after the country’s accession to the World Trade Organization in 2001.

Rising import exposure also reduced employment, revenue, available capital, market valuation, and research and development (R&D) expenditure at U.S. firms, according to the report.